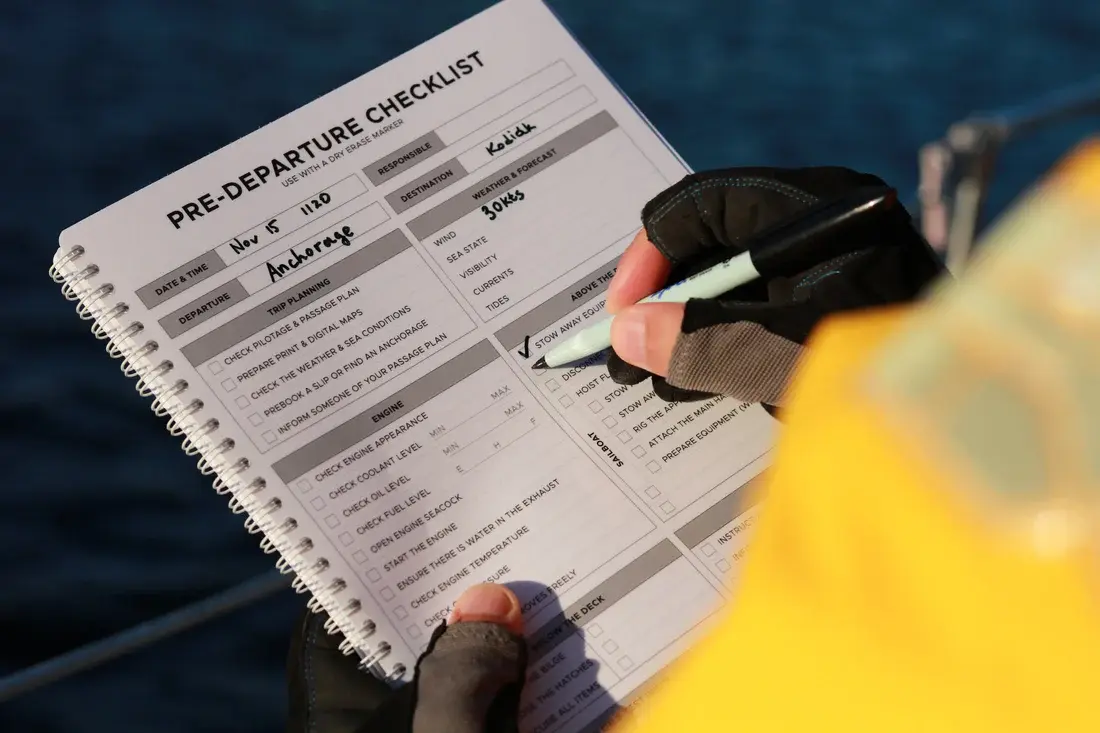

In complex operational environments, whether in maritime, aviation, manufacturing, energy, or logistics, human error, oversight, or process drift are ever‑present risks. Checklists have become proven tools to guard against those risks by enforcing structured routines and ensuring that critical steps are never omitted. In modern contexts, a digital operations checklist can dramatically enhance those safeguards by integrating real‑time validation, traceability, and data analytics.

A digital checklist is an electronic version of a conventional paper or laminated checklist, deployed via tablets, mobile devices, or integrated systems. Such checklists replace manual, paper‑based processes with structured, enforceable, traceable workflows. (Ocasta)

Digital Checklists in Operations

Checklists have long been adopted in domains where mistakes can be costly or dangerous e.g. aviation pre‑flight checks, surgical checklists, nuclear control, etc. The core rationale is that even highly trained humans are fallible and can omit steps under stress, fatigue, or complexity. A checklist acts as an external memory aid and a procedural guardrail.

Some of the general benefits include:

- Reduction of errors of omission: A checklist helps ensure that every critical step is performed and no step is forgotten.

- Standardization: All operators use the same checklist, reducing variation in how tasks are performed.

- Auditability: A record of what was done, by whom, and when.

- Training and consistency: New staff can rely on established procedural guidance.

- Operational discipline: Checklists can help ensure that even in routine tasks, the essential checks are not skipped or disregarded over time.

In the maritime sector, for example, checklists (and forms) are integral to regulatory compliance, operational efficiency, and safety management systems. According to VoyageX AI, checklists help ships comply with regulatory regimes such as the ISM Code and SOLAS, streamline workflow, and reduce errors. (VoyageX AI)

The transition to digital checklists further strengthens these benefits and addresses several limitations of paper:

- Real‑time visibility and monitoring: Supervisors or shore offices can see checklist progress, flag deviations, and intervene. (Fluix)

- Automated reminders and enforcement: The system can prompt or even block continuation unless certain checks are completed.

- Version control and updates: As procedures evolve, digital checklists can be centrally updated and distributed to all users.

- Integrated data capture: Beyond check boxes, systems can capture measured values (e.g. pressures, temperatures), images, comments, and time stamps.

- Trend analysis and predictive insights: By aggregating checklist data across time and assets, patterns of non‑compliance or drift can be detected.

- Improved accountability: Who did what and when is logged, increasing ownership and traceability.

- Reduced paperwork burden: No need for printing, scanning, or archiving large volumes of paper.

The checklist is a foundation for operational integrity, a bridge between frontline execution and supervisory oversight, and an enabler of continuous improvement.

Digital Checklist in Maritime Operations

The maritime domain is a fertile ground for applying digital operations checklists, due to the high stakes (life, environment, regulatory exposure) and complex operations.

A study titled Use of checklists and potential of the introduction of digital checklists onboard vessels examined how checklists are used on ships and the potential of digital versions. (ResearchGate) Some findings from that study include:

- Many vessels currently use paper or laminated checklists, but these have limitations in terms of traceability, version control, and enforcement.

- A digital checklist could allow better monitoring, timely updates, and integration with other ship systems.

- Crew acceptance and human factors (ease of use, reliability, user interface) are critical success factors for adoption.

- Digital checklists help shift from reactive corrections to more proactive maintenance and safety oversight.

Further, the maritime industry already employs a variety of checklists (pre‑departure, safety rounds, maintenance, emergency procedures, dry docking, etc.). Falcony’s blog identifies “12 essential checklists in the maritime industry,” covering items like ship departure, bunkering, cargo operations, safety rounds, maintenance, etc. (ResearchGate) These checklists provide the scaffolding for standard operating routines.

VoyageX also emphasizes that departmental checklists (e.g., HR, accounts, technical, safety) are used in shipping operations to document all necessary activities, improving both efficiency and compliance. (VoyageX AI)

Classification Societies have moved toward dynamic checklists (i.e. checklists generated in real time based on vessel type, survey requirements, etc.). As one article notes:

“ABS announced the introduction of electronically prepared, vessel type‑specific, dynamic checklists … The surveyor is automatically provided with a checklist specific to the type of vessel … the dynamic checklist module can produce approximately 600,000 unique checklists … the system does not allow the surveyor to close the survey report without addressing each item on the checklist.” (MarineLink)

Advantages to maritime operations

- Better oversight and communication between ship and shore: Digital checklists allow shore teams to monitor progress, identify delays or deviations, and respond promptly. (Fluix)

- Audit support and compliance demonstration: Completed checklists are stored, timestamped, and exportable (e.g. PDF) for audits or investigations. (Marine Cloud)

- Reduced human error in maintenance: By embedding triggers, linking to manuals, and including check paths, the digital format helps reduce maintenance omissions or missteps. (StarNapp)

- Efficiency gains: Time saved from redundant paperwork, scanning, and manual archiving can be repurposed for safety oversight or more value‑added tasks.

Given the scale of maritime operations (multiple vessels, many checks per voyage, regulatory risk), the cumulative benefit of digital checklists is substantial — both in risk mitigation and cost avoidance.

Checklist Implementation

Implementation of checklists requires conscientious design and execution. Some key principles and best practices include:

-

User-Centered Design and Simplicity

The checklist interface must be clean, intuitive, and tailored to crew workflows. Complex or cluttered displays discourage adoption. In one human‑computer interaction study, errors like marking tasks prematurely and failure to record values were frequent when the design was poor. (ACM Digital Library) -

Contextual / Dynamic Logic

Smart checklists adapt to the vessel, operation type, or conditions, excluding irrelevant items. This reduces “noise” and improves focus. ABS’s dynamic checklists exemplify this. (MarineLink) -

Mandatory Enforcement

For critical steps, the system should prevent further progression until key tasks are marked done, or prompt verification. This helps prevent skipping steps under pressure. -

Offline Capability and Resiliency

Ships may have intermittent connectivity; checklists must work offline with syncing later. Backup strategies and version resilience are crucial. -

Integration with Other Systems

The digital checklist should not exist in isolation but rather connect with maintenance systems, safety management systems, performance dashboards, spare parts databases, etc. This linkage enhances value and avoids data silos. -

Change Management and Crew Buy‑in

Transitioning from paper to digital involves cultural shift. Training, demonstrations, and iterative refinement with crew feedback are essential for acceptance. -

Version Control and Update Mechanisms

Procedures evolve; checks must be kept current and rolled out reliably to all vessels. Versioning, review approval, and controlled deployment help maintain consistency. -

Data Analytics and Continuous Improvement

Use aggregated checklists data to identify recurring nonconformities, drift in compliance, or process inefficiencies. Over time, refine the checklist itself. -

Security, Access Control and Audit Logs

Records of who modified, approved, or completed a checklist step, including date and time, must be kept. Access control ensures that unauthorized changes are prevented. -

Fallback and Redundancy

In rare cases such as device failure or power outage, there should be a fallback such as synchronized paper or alternate systems to ensure operations don’t halt.

Challenges and Risks

Digital checklist adoption also faces challenges:

- Resistance to Change: Some crews may resist digital transition, favoring familiar paper checklists. Adaptation takes time.

- Technology Reliability: Device failures, software bugs, or network issues could undermine trust in the system.

- Usability Pitfalls: Poor interface design such as crowded screens or unclear prompts can lead to misuse.

- Overhead and Initial Costs: Training, devices, software licensing, integration — the upfront investment can be significant.

- Data Integrity / False Completion: Users might superficially mark checks as done without actual inspection, especially if oversight is weak.

- Cognitive Load: In complex, emergent situations, following strict checklist order may slow responsiveness.

- Version confusion or drift: If multiple versions circulate, inconsistency may arise.

Checklists as an Operational Foundation

As industries increasingly adopt digitalization, the checklist can become a foundational pillar of operational integrity:

- Augmented Reality: In the future, checklists may link directly to sensor data, prompt inspections only when thresholds are approached, or guide tasks via AR overlays.

- Predictive maintenance feedback: By correlating checklist data with equipment failures, it becomes possible to anticipate issues earlier.

- Cross‑fleet benchmarking: Aggregated data across multiple vessels or facilities offers insights into best practices and outliers.

- Regulatory and certification alignment: Standardization of digital checklists may enable regulators or classification bodies to verify compliance more directly.

- Continuous evolution via feedback loops: The checklist is not static, it evolves, informed by field data, risk assessments, and human feedback.

The checklist is not just a checklist on a screen. It is the digital nervous system of operations, supporting execution quality, oversight, improvement, and resilience.

Conclusion

The checklist is a powerful enabler of operational integrity, safety, and efficiency. In domains such as maritime operations, where procedural rigor and regulatory compliance are nonnegotiable, transitioning from paper to digital checklists yields concrete benefits: real‑time visibility, enforceability, auditability, traceability, and actionable analytics.

However, successful adoption depends not just on software, but on good design, robust integration, user acceptance, offline resilience, and continuous improvement. With those in place, the checklist becomes more than a procedural guard, it becomes the operational backbone.